ACO Passavant product information and installation

ACO has developed and refined its Passavant range of gravity grease traps that provide comprehensive service to the commercial kitchen and food processing industries, designed to separate Fats, Oils, and Grease (FOG) from wastewater in these environments.

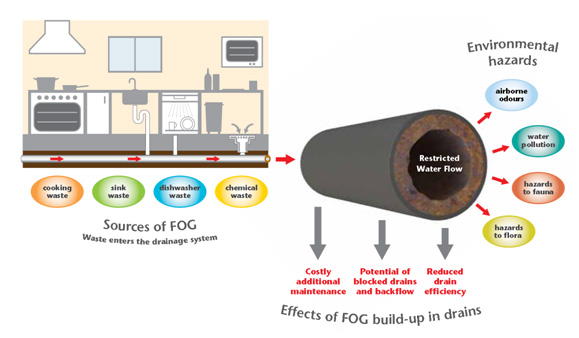

When cleaning cooking utensils, crockery and equipment, residual FOG runs down through the drains and can cause odours as well as pipe blockages, which can lead to flooding and result in expensive maintenance work. FOG can also cause pollution to the environment and be a serious health risk. To prevent the pollution of FOG, there are regulations in Australia that must be followed. Commercial kitchen and food processing facilities are required to have grease traps installed otherwise they face severe legal ramifications.

To ensure that kitchens and food processing facilities maintain the industry-level regulations, ACO has developed above and below ground grease traps. Either type may be use, depending on the facility and application requirements. The below ground grease trap, Lipumax, is installed beneath the ground surface, while the EcoJet model is positioned on the ground surface. The ideal choice of trap type is dependent on several factors including location within the facility, and the space available.

To ensure that kitchens and food processing facilities maintain the industry-level regulations, ACO has developed above and below ground grease traps. Either type may be use, depending on the facility and application requirements. The below ground grease trap, Lipumax, is installed beneath the ground surface, while the EcoJet model is positioned on the ground surface. The ideal choice of trap type is dependent on several factors including location within the facility, and the space available.

Once a trap type is selected, there are four more key considerations:

Construction materials – The materials used in the manufacture of a grease trap will affect the life and performance of the product.

Regulations – Local and international regulations dictate the specifications of above and below ground grease traps.

Access for maintenance – Depending on where you plan to install grease traps, they must have dedicated access points for ease of maintenance.

Buoyancy – When installing grease traps below ground, designers must consider the impact of high water table areas.

To ensure that businesses have the best-designed below ground grease traps, ACO has developed Lipumax. Designed specifically for strength and durability, Lipumax is constructed from corrosion-resistant polyethylene to ensure longevity. The ovoid shape of the system allows soil to be compacted tightly around the body to prevent buoyancy, whilst ribs moulded onto the trap’s exterior interlock with the soil or concrete around it to create friction. A load distribution plate can be added to the unit for additional weight if required. To help a business decide which model best suits their purposes, ACO offers a number of access covers with a choice of load classes certified to AS 3996.

ACO has also developed EcoJet above ground grease traps. As with Lipumax, EcoJet is designed from the same corrosion-resistant materials, giving the model a design life of at least 25 years of high performance use. EcoJet’s compact design takes up as little space as possible and its shape allows for easy manoeuvrability during installation.

Both Lipumax and EcoJet have been certified by numerous Australian water authorities and councils for high performance, allowing it to process large volumes of wastewater.

If you want to find out more about any of ACO’s grease trap products or how ACO products can aid in creating an environmentally-friendly and industry-compliant workplace, please call 1300 765 226 to speak with an expert – or contact us now via email.